Ruger American Lock Ring Wrench

- By Dale Hegstrom

- •

- 10 Dec, 2018

- •

Procrastination

I’ve been procrastinating for a while about creating a blog, but now I’ve found the perfect opportunity.

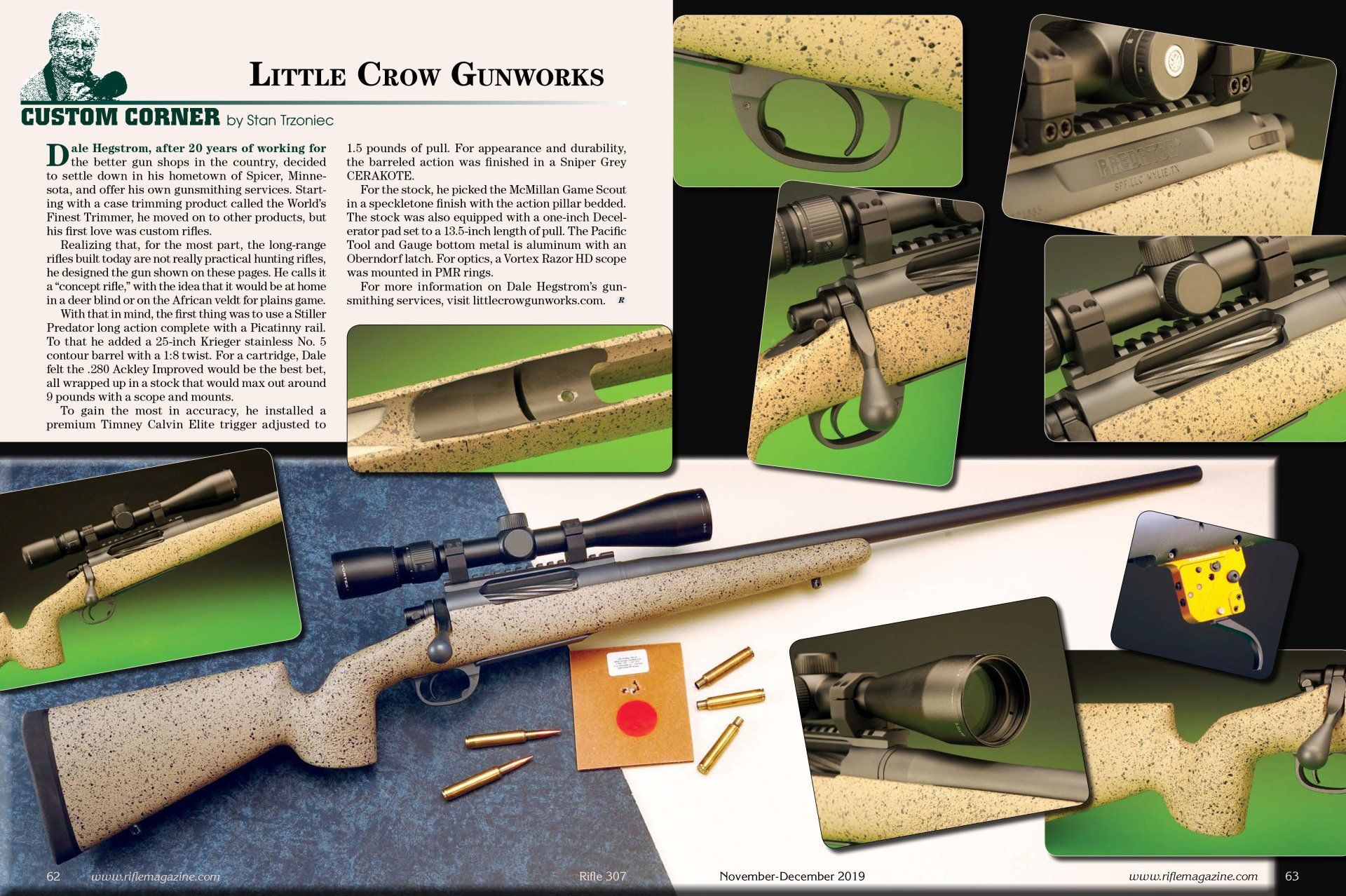

I’d like to introduce our LRW which is short for Ruger American Lock Ring Wrench. I became a fan of the Ruger American rifle a few years ago. The American’s price, ruggedness, and features make it a natural for a working truck gun. Of course, after you play with a gun for a while, you start to get ideas how you can tinker with it to make it even better.

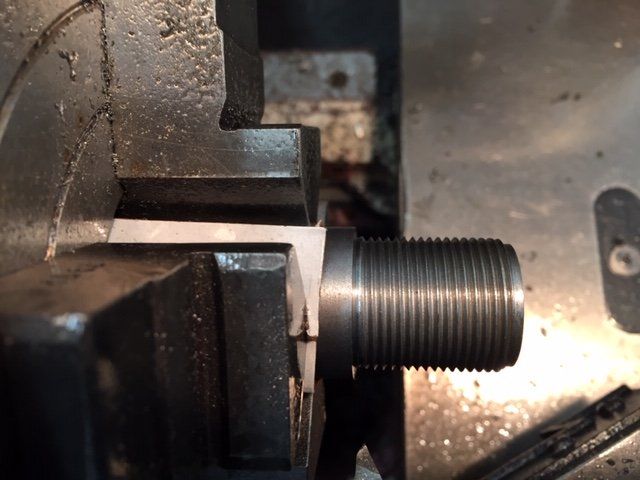

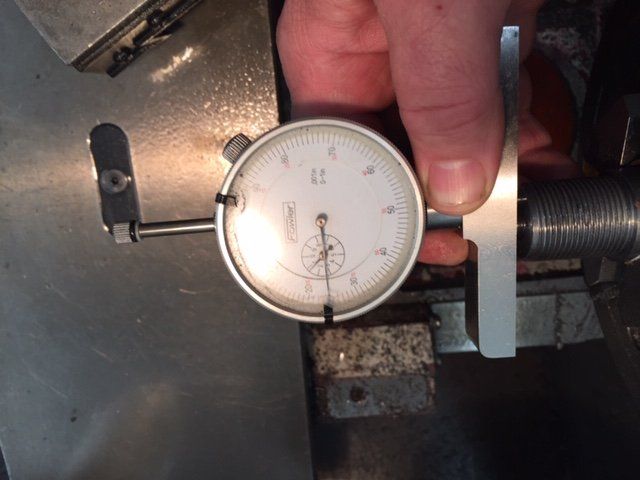

I had been putting together a .223 Ackley on a Remington 700 with a 27” 1-8” twist barrel for a long- range rifle that would be cheap to handload rounds for. I didn’t really want to shoot hundreds of rounds fire forming brass through my Krieger barrel, so I decided to re-barrel the .300 Blackout barrel on my Ruger American. I decided to use a factory Remington take-off barrel on the Ruger and form the Ackley brass while hunting prairie dogs. Much to my surprise, I discovered no one was making a wrench for the American and a Savage wrench wouldn’t work. What I came up with is a rugged economical design. (Image 1)

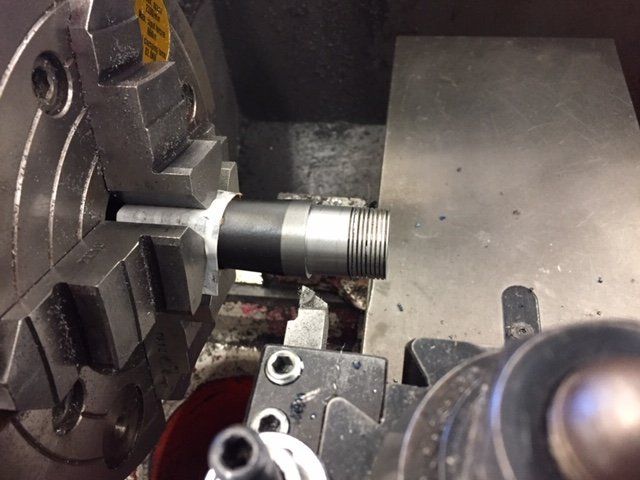

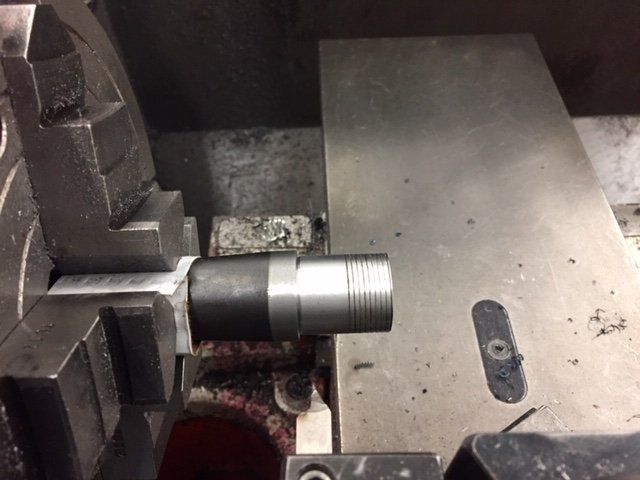

I thought customers might find it interesting how I re-machined the Remington barrel to fit on the American. The steps are shown as follows:

1/7/19

6.5 Creedmoor Blog

Usually a couple evenings a week I will go on the computer and check out the shooting forums just to see what’s going on in the Industry. I don’t respond to threads, but they do give me a lot of food for thought. Sometimes this has lead me to doing my own experiments and rifle projects.

Lately I’ve noticed an incredible amount of negativity towards 6.5 Creedmoor or anything Creedmoor. It’s pretty comical how much hatred can be directed towards an animate object. It’s a lot like the Ford vs. Chevy argument, who cares as long as you are getting from point A to point B. Most of these arguments go something like this, “How can a 6.5 Creedmoor be better than my .260 or 6.5x55 Swede?” Most of these guys are handloaders so the reality is there really is not much difference. The main difference is the Creedmoor was developed at the beginning of the long range revolution. It was designed from the ground up to be a long range match cartridge using the new VLD bullets to easily fit in a standard short action magazine.

Once Laser rangefinders and Mildot-tactical turret scopes became readily available, the weak link became ammunition. This was not a problem for the handloader who could build ammo to fit his rifle. However if you didn’t have the time or where with all to make your own ammo, you were stuck with what was available on the open market. Don’t get me wrong, Ammunition companies are doing a fantastic job making ammo especially the semi-custom guys, but they still must make ammo to fit every gun out there. And that’s where the 6.5 Creedmoor comes in, The Creedmoor could be called a ballistic system. From what I understand, the chamber reamers for 6.5 Creedmoor are supposed to be ground to a specific dimension, so all rifle chambers should be pretty close to a specific dimension, which makes it much easier for an ammo maker to make ammo that should be more uniform as far as pressure and accuracy.

The first rifle I built back in 2009 for the 6.5 Creedmoor put together a .210” five shot group at 100 yards for its first group. Five years later I put together my first AR rifle in that caliber and it averaged less than ½ MOA for its first four 5 shot groups. Both these guns were shooting off the shelf Hornady ammo. We put a fair number of rifles together each year and when someone wants to put together a long range rig and does not handload I usually talk to them about considering a Creedmoor.

- Sunday

- Closed

- Mon - Fri

- -

- Saturday

- Appointment Only

All Rights Reserved | Little Crow Gunworks, LLC